ZZ-V-25E

3.3.1.3 Bridge washer. Each type I, class 2, style A and Class 7 valve shall, when specified (see

6.2), be furnished with a bridge washer suitable for its intended purpose.

3.3.2 Cap. Unless otherwise specified (see 6.2) , caps shall be furnished and shall conform to the

applicable reference (see 1.2.1) and may be screwdriver, swivel sealing type (TR VC2) , dome, swivel

sealing type (TR VC3 ) or dome, polyethylene dust cover type (TR VCB).

3.3.3 Core.

3.3.3.1 Core fit. Unless otherwise specified (see 6.2) , cores shall conform to the applicable

reference (see 1.2.1) . Cores supplied for replacement shall fit as do original cores without modification

of cores or valves.

3.3.3.2 Deflation by core Cores shall be so constructed that when installed for use, tire pressure

can be decreased by depressing the core plunger pin. It shall not be necessary to remove e core from

th

the valve to deflate the tire or tube.

3.3.3.3 Core plunger pin height. Core design shall be such that when the core is properly lns.tailed,

the tip-on the core plunger pin shall position .035" below to .010" above the valve lip.

3.3.4 Spud.

Unless otherwise specified (see 6 .2) , spuds shall conform to the applicable reference

(see 1.2.1).

3.3.5 Grommet. Unless otherwise specified (see 6.2) , grommet design characteristics shall conform to

MS-52120 (AT) and be capable of its Intended purpose.

3.3.6 Nut, hexagon,plain. Unless otherwise specified (see 6.2) , design characteristics shall reform

to MS-52119 (AT) and be capable of its intended purpose .

3.4 Physical properties.

3 4.1 Valves.

Valves with rubber bases shall conform to the pull values of Table I.

3.4.1.1 Tensile strength.

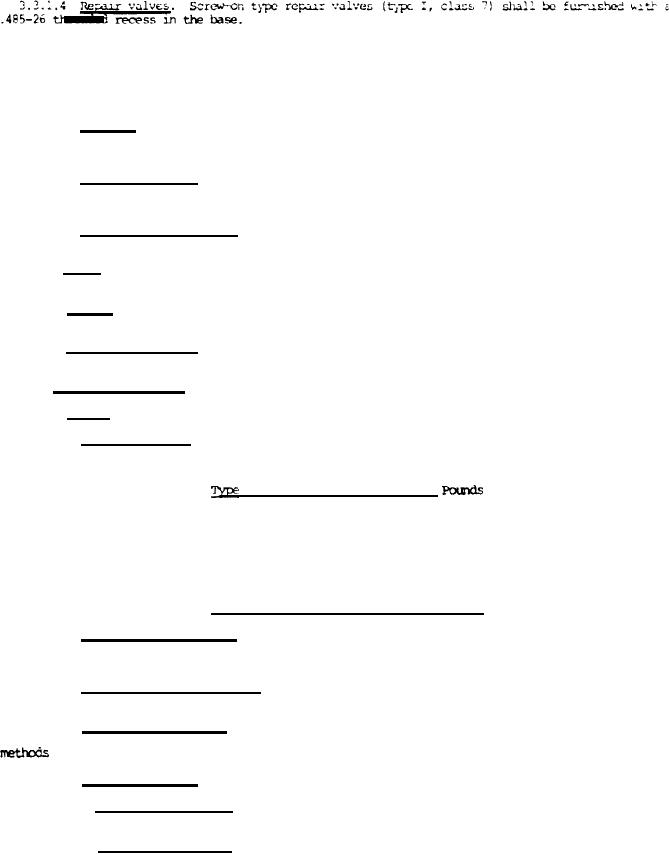

TABLE I.

Least allowable tensile strength values

Class

100

1

I

2

300

100

3

4

100

100

5

100

6

III

1

300

300

2

4

300

3.4 .1.2 Valve stern base closure. Valves, type 1, classes 5 and 6, shall have sufficient spinning or

closing of the inner well of the metal groove to effect a mechanical lock of the rubber in the groove.

There shall be no cracks or flaws in the stem wall.

Valves, type 11, class 1, shall have no cuts or cracks in the

3.4.1.3 Crack resistance of rubber.

rim-hole sealing area.

3.4.1.4 Distortion resistance Valves, type I, classes 1 and 5, shall be of such a strength and

hardness as to prevent distortion or other damage when subjected to proper field mounting and servicing

3.4.1.5 valve bendability

Valves, type i, class 1, style B, and class 5, style B, shall permit

3.4.1 .5.1 Hard-bendable valves

hard-bending once without cracking.

3.4.1 .5.2 Tool-bendable valves. Valves, tyupe I, class 2 {except TR70) , and TR87 from class 3, style

A, shall permit tool-bending once without cracking.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business