ZZ-V-25E

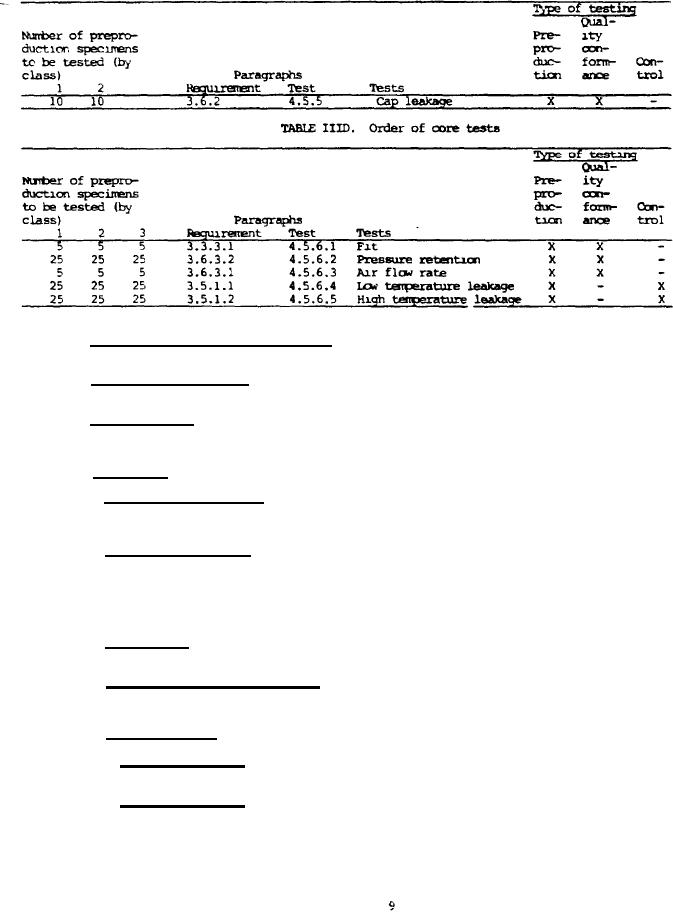

TABLE IIIC. Order of cap tests

4.5.1 Temperature and pressure conditions. Unless otherwise specified herein, all testing shall be

conducted at ambient conditions of temperature (77° ± 12°F.) and pressure (14.5 psis ± .2 psia).

4.5.2 Valve core installation. Unless otherwi se specified herein, type V, class 2 cores shall be

torqued to 1-1/2 to 3 pound-inches, and type v, class 3 cores shall be torqued to 3 to 5 pound-inches.

4.5.3 Leakage testing. All leakage tests shall be accoplished by (a) completely immersing the test

assembly in water or alcohol with the valve stems positioned mouth down, or (b) using automatic test

equipment, as applicable, to the intended use and test conditions.

4.5.4 Valve tests.

4.5.4.1 Durameter hardness test. To determine conformance to 3.4.1.6, the rubber compound shall be

subjected to the durameter hardness test specified in method 3021 of Fed. Teat Method Std. No. 601, using

a type A Shore durameter.

4.5.4.2 Tensile strength test. To determine conformace to 3.4.1.1, valve stems specified in Table

I shall be pulled to destruction at the rate of 5 inches per minute in a tensile machine. In preparation

for the test, the cap shall be removed and the valve stem shall be firmly and completely mated in the

threaded adapter of the pull mechanism while the valve assembly base is clamped into a fixture with an

adapter ring. The adapter rig shall have an inside diameter of 3/4" for type I, classes 3 and 4 valve

assemblies and 1-1/4" for type 1, classes 1, 2, 5, and 6 valve assemblies.

4.5.4.3 Closure test. To determine conformance to 3.4.1.2, the rubber-base stem of the valve being

tested shall be cut to expose the degree of closure in the valve stern base.

4 .5.4,4 Crack resistance of rubber test. To determine conformance to 3.4.1.3, the straight lenght of

the rim hole sealing area shall be stretched 10 percent to elongate the section sufficiently to permit

visual examinatiion.

4.5.4.5 Bendabilty test.

4.5.4 .5.1 Hand-bendable test. To determine conformance to 3.4.1.5.1, valve stern shall be examined

after being hand-bent to an angle of 69° ± 1° while the lower portion is held solidly in a fixture

4 .5.4.5.2 Tool-bendable test. To determine conformance to 3.4.1.5.2, valve stem shall be examined

after being bent by standard valve bending tools to 86° at the valve base end, and length permitting to

90° at not less than 1-1/2" from cap end.

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business