MIL-DTL-45301E

4.9 Operating requirements verification.

4.9.1 Performance test.

4.9.1.1 Physical properties. To determine conformance to 3.5.2, physical properties

specified in table III shall be determined on specimens cut from the platen press sheets specified in

4.6.3. Tests shall be in accordance with ASTM methods as specified in table VII. Curing tests

may be substituted with a certification from the contractor that any elastomer failing to meet the

requirements of 3.6.1 will be replaced at no cost to the Government.

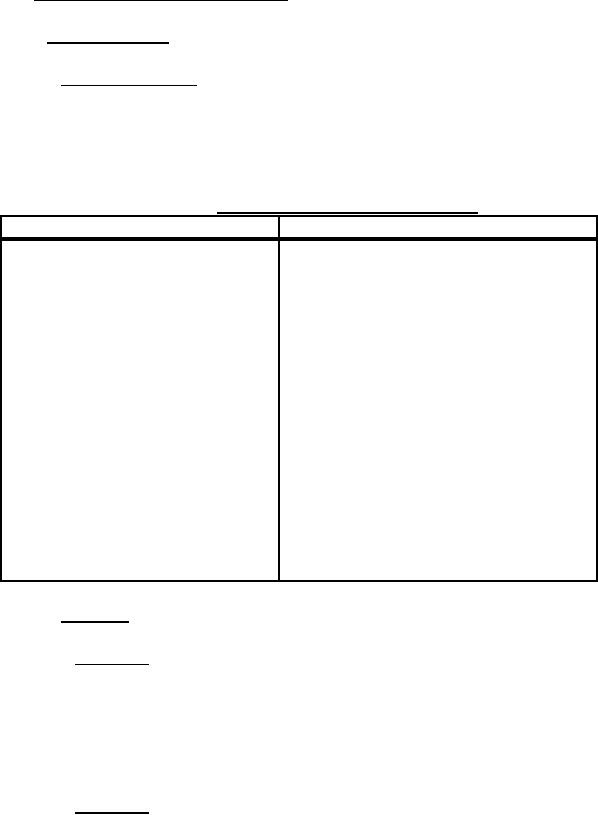

TABLE VII. Test methods for physical properties.

Physical property

Method number

Hardness

ASTM D1415 or ASTM D2240

Tensile strength

ASTM D412

Elongation, ultimate

ASTM D412

Tensile stress, (modulus)

ASTM D412

Accelerated aging of tensile and

ASTM D573

elongation (air heat test, air

heating medium)

Specific gravity

ASTM D792

Ozone resistance test (resistance to ASTM D518 & ASTM D1149

surface cracking of stretched

elastomer compounds)

Low temperature flexibility test

ASTM D2137, Method A

Mooney viscometer test (Viscosity

ASTM D1646

and curing characteristics of

elastomer by shearing disk

viscometer)

4.9.1.2 Adhesion.

4.9.1.2.1 Apparatus. To determine conformance to 3.5.3, a tension testing machine

having a power-actuated clamp shall be used to apply and measure the force required to strip the

tire from the metal wheel or rim to which it is adhered. The clamp shall travel at a rate of 6 in.

(152 mm) per minute. The machine shall be provided with means for accurately measuring the

applied tension. A hub and spindle assembly shall be provided for mounting the tire and

permitting it to rotate fully about a fixed axis.

4.9.1.2.2 Procedure. The tire shall be prepared for testing by cutting down to the metal

wheel or rim circumferentially along its edges on both sides to minimize tearing. The tire shall

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business