MIL-DTL-45301E

2.3 Order of precedence. In the event of a conflict between the text of this specification

and the references cited herein, the text of this specification takes precedence. Nothing in this

document, however, supersedes applicable laws and regulations unless a specific exemption has

been obtained.

3. REQUIREMENTS

3.1 First article. When specified (see 6.2), a sample shall be subjected to first article

inspection in accordance with 4.1.2.

3.2 Material.

3.2.1 Tread elastomer. The chemical compounding of tread elastomer shall be such that

all classes and sizes of both groups are black in color. When Group B, P-12 material is furnished,

the compound formulation is in accordance with table I (see 4.6.1).

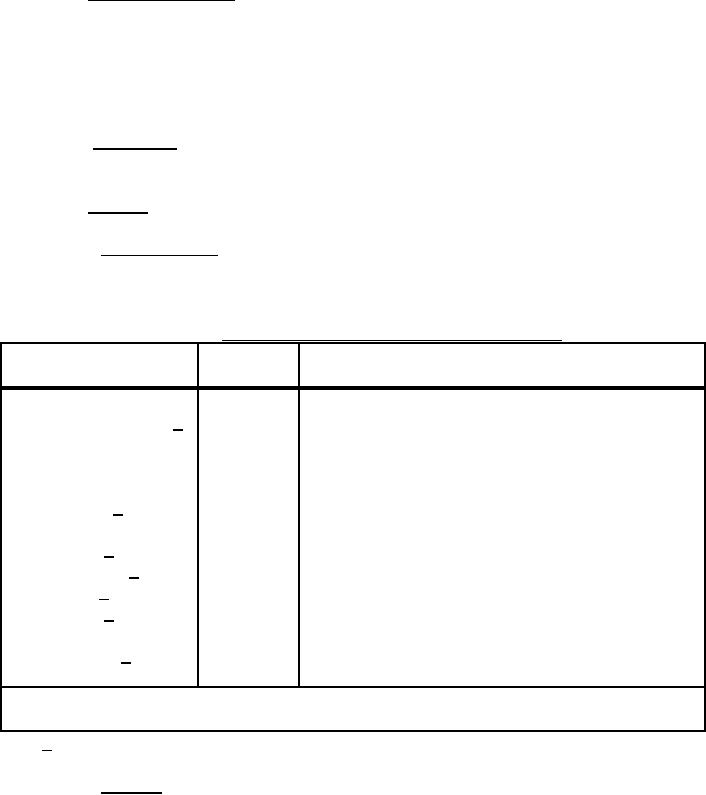

TABLE I. Compound formulation Group B, P 12 material.

Relative

Materials

weight

Chemical composition

SBR 1500

70.00

Polymer

Cis-4 1203 or CB 220 1/

30.00

Polymer

Zinc oxide

3.00

Stearic acid

2.00

N220 carbon black

62.00

Flexzone 7-L 1/

3.00

(N-1, 3-Dimethybutyl-N'-phenyl-p-

phenylenediamine)

Sunolite 100 1/

1.50

(Blend of Waxy Hydrocarbons)

Agerite Resin D 1/

2.00

(Polymerized 2, 2,4-trimethyl-1, 2-dihydroquinoline)

Sundex 790 1/

2.00

Oil

Nobs special 1/

1.20

[N-oxydiethylene-2-benzothiazole-sulfenamide

(2-morpholinothio) benzothiazole]

Santogard PVI 1/

0.20

[N-(cyclohexylthio) phthalimide]

Sulfur

1.60

178.50

Total Formula Weight

1/ Substitution may be made with chemical equivalents from other manufacturers.

3.2.2 Tie gum. When specified (see 6.2), tie gum shall be elastomer. Tie gum shall not

include any reclaimed rubber (see 4.6.2).

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business